So I have some whacky questions for the day. I just blew a rod on my 04 at the track yesterday and am surveying the damage and looking at my options to get things fixed. I had a few different ideas I'm chasing down and figured I'd throw some wild longshot questions out there while I was at it.

The first one is will a gen 4 crank physically fit in a gen 3 engine? The ****** appears to be the same. I know the gen 4 uses a crank mounted tone wheel, but my 04 uses a flywheel crank trigger, so I would just ignore the crank one, assuming it doesn't cause interference issues in the block. Along those lines, is the oiling setup in the gen 4 crank any different than the gen 3? I have read about plugging some of the holes on the main journals to prioritize rod oiling, but I wasn't sure if this was unique to the earlier gens or something that is still present on the gen 4+ cranks. I toasted the 3/4 journal all over again on a rebuild with only 5000 miles on it and a fresh oil change right before the track. I run street tires on a course with limited high speed sweepers, so I really don't think a swinging pickup would have made any difference, though I could be wrong. Just trying to understand how the gen 4 oil system is different than a gen 3.

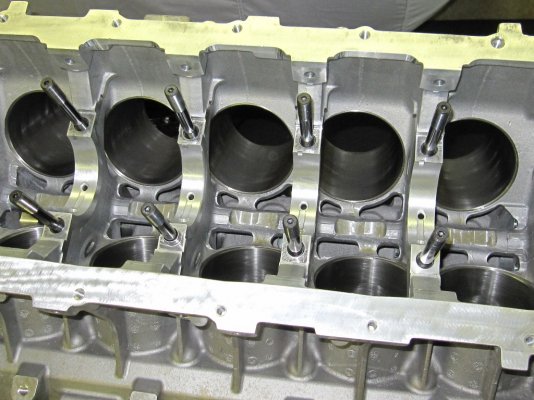

Second wacky question for the day. Will gen 3 parts bolt on to a gen 4 block? IE could I take a gen 4 short block and bolt all of my gen 3 stuff to it (heads, front cover, accessories, etc.)? How different are the blocks themselves? I know the bore is slightly different (0.5mm or so) and the gen 4 has the variable cam, but I wasn't sure if the block had anything to do with that. I thought it was more in the timing cover, but maybe not. I'm a little more interested in this particular idea as my block has a fair amount of damage from the rod letting go and I'm thinking I'm going to need a new one one way or the other. It might be salvageable, but at this point I think a short block is going to make more sense to get the car back on the road. I'm looking for gen 3 stuff to start with, but didn't know if a gen 4 short block might be another interesting option just to open up the amount of parts that might be out there to look for. Same issue with the crank trigger, but if I'm triggering off the flywheel it seems like I could just leave the gen 4 sensor in place as a plug and do nothing with it.

Anyone else out there done any frankenstein work like this? I know more people put gen 4 parts on a gen 3, but figured if that worked them maybe the opposite would as well. I'm looking for a short block regardless at this point, but until I get the whole engine out I'm not sure the full extent of the damage. Pretty sure I can salvage the top end at least. Hoping my cam and lifters are still okay, but won't know until I get them pulled out.

The first one is will a gen 4 crank physically fit in a gen 3 engine? The ****** appears to be the same. I know the gen 4 uses a crank mounted tone wheel, but my 04 uses a flywheel crank trigger, so I would just ignore the crank one, assuming it doesn't cause interference issues in the block. Along those lines, is the oiling setup in the gen 4 crank any different than the gen 3? I have read about plugging some of the holes on the main journals to prioritize rod oiling, but I wasn't sure if this was unique to the earlier gens or something that is still present on the gen 4+ cranks. I toasted the 3/4 journal all over again on a rebuild with only 5000 miles on it and a fresh oil change right before the track. I run street tires on a course with limited high speed sweepers, so I really don't think a swinging pickup would have made any difference, though I could be wrong. Just trying to understand how the gen 4 oil system is different than a gen 3.

Second wacky question for the day. Will gen 3 parts bolt on to a gen 4 block? IE could I take a gen 4 short block and bolt all of my gen 3 stuff to it (heads, front cover, accessories, etc.)? How different are the blocks themselves? I know the bore is slightly different (0.5mm or so) and the gen 4 has the variable cam, but I wasn't sure if the block had anything to do with that. I thought it was more in the timing cover, but maybe not. I'm a little more interested in this particular idea as my block has a fair amount of damage from the rod letting go and I'm thinking I'm going to need a new one one way or the other. It might be salvageable, but at this point I think a short block is going to make more sense to get the car back on the road. I'm looking for gen 3 stuff to start with, but didn't know if a gen 4 short block might be another interesting option just to open up the amount of parts that might be out there to look for. Same issue with the crank trigger, but if I'm triggering off the flywheel it seems like I could just leave the gen 4 sensor in place as a plug and do nothing with it.

Anyone else out there done any frankenstein work like this? I know more people put gen 4 parts on a gen 3, but figured if that worked them maybe the opposite would as well. I'm looking for a short block regardless at this point, but until I get the whole engine out I'm not sure the full extent of the damage. Pretty sure I can salvage the top end at least. Hoping my cam and lifters are still okay, but won't know until I get them pulled out.